Table Of Content

The final question to answer is if the platform offers the features you need and if those features integrate with other tools you are using today. Mangomint would, for example, give you access to features like an intelligent waitlist, intake forms, gift cards, smart payment processing, automated reminders, staff management, and much more. Many salon software forces you to leave the website and go to their site to book.

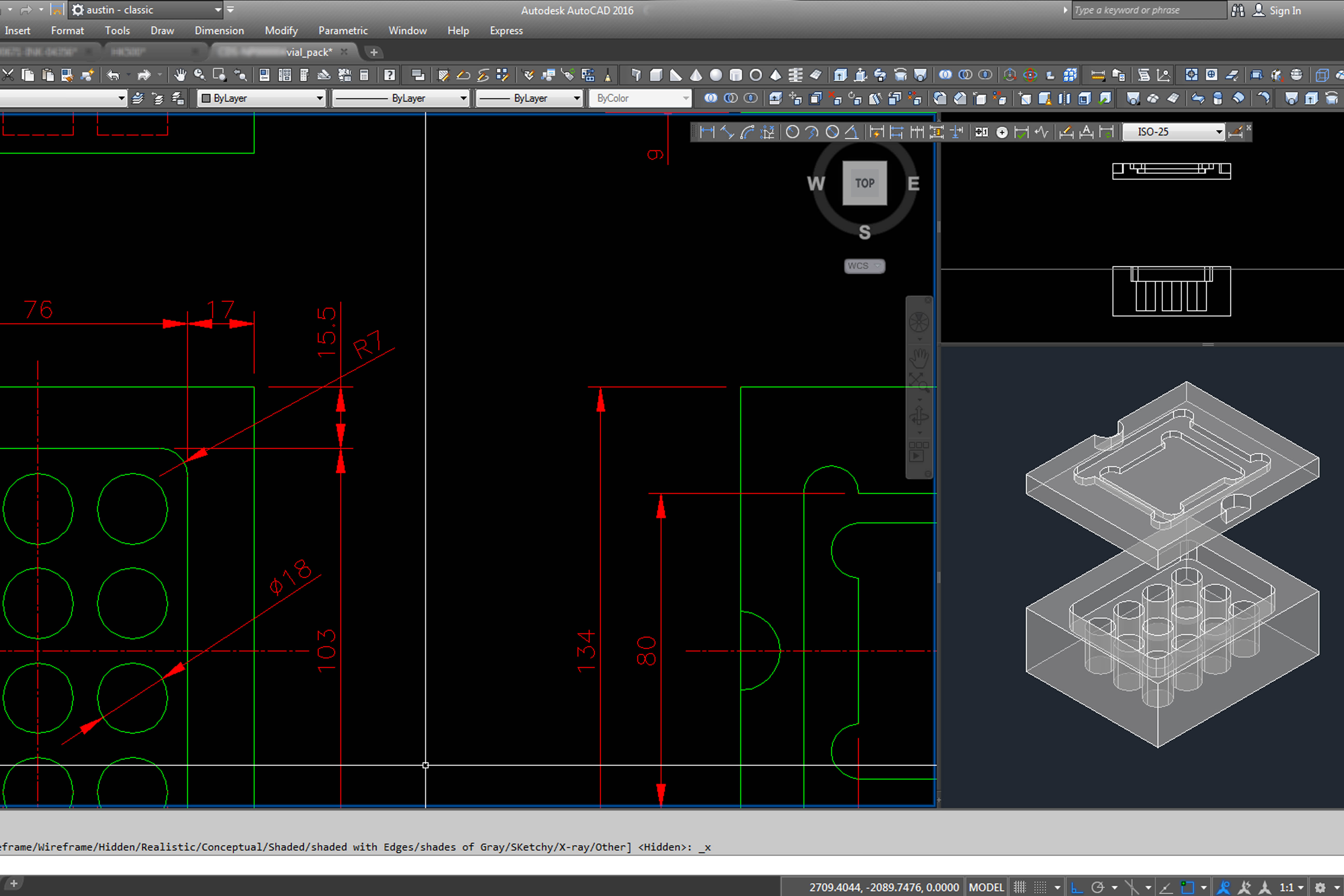

The Role of DFM in Bridging the Gap Between Design and Manufacturing

APriori also boosts manufacturers’ digital thread investments to deliver business value at scale, increase agility, and minimize risk. In addition to running manufacturing simulations quickly, the output of the analysis should be extremely easy to interpret. Identification of potential manufacturability issues should be highly graphical and pinpoint areas for improvement. For example, the system should be able to quickly identify any machining operations where the cycle time is abnormally high. While there may be a good reason for this, it may also identify a design flaw that, if corrected, could dramatically accelerate the manufacturing process and drive down cost accordingly.

DFM Principles

He has several years of experience in Education Administration, Student Services and Student Engagement. He has worked with FE and HE institutions across different European countries including Spain, UK, Denmark, Italy and Belgium. He specialises in bridging the gap between architectural design and robotic construction. He has previously taught at the Architectural Association (UK) and RWTH (Germany). Prior to teaching, he worked with Archi-Union (China) & RSP (India) as an architect.

Cantu Shea Butter Tea Tree & Jojoba Hair & Scalp Oil

“When it comes to styling fine hair types—a root lifter/volumizer is a must,” says Stevens. Customers also love this spray because it creates body in the hair without feeling sticky or stiff. This dry finishing spray is also crafted for all hair types and creates instant volume and texture for a sexy bedhead look. Users should be able to easily view available appointments, select their preferred service, and confirm their booking without making a phone call or sending an email.

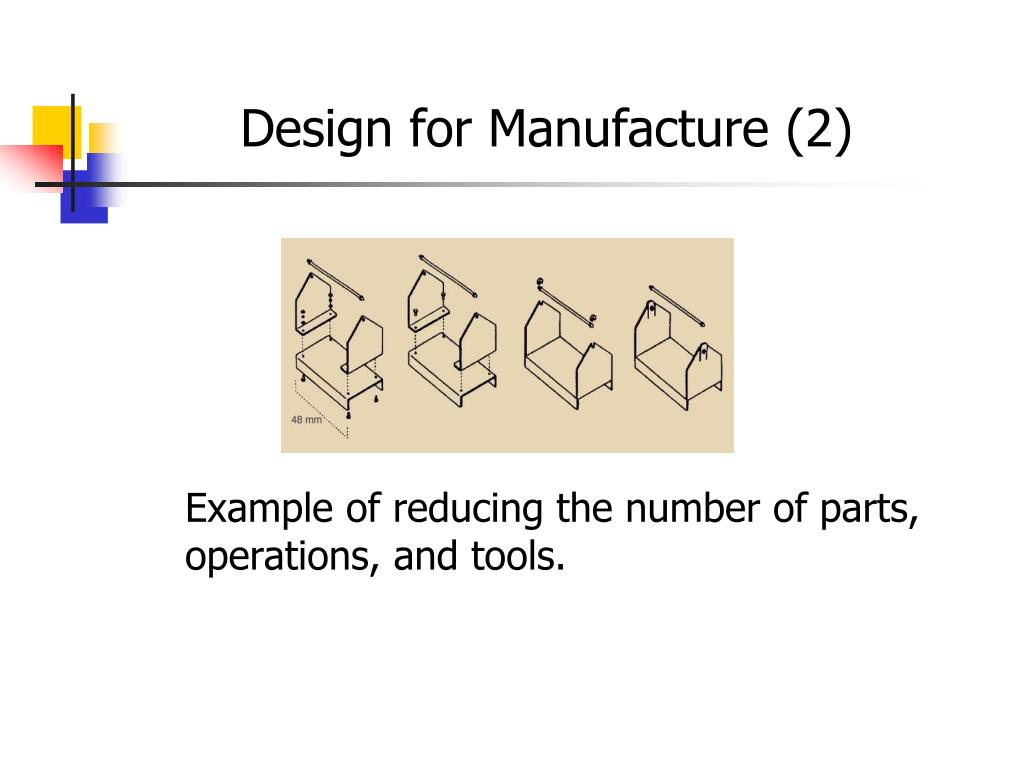

The capacity to generate intricate textures, patterns and geometries is only one of the many design freedoms made possible by additive manufacturing. AM can merge dozens of separate components into one or condense assembly into one, like two sides of a hollow item. This has the potential to reduce the number of steps, materials, suppliers, glue, fasteners and total parts required to make a certain item. Organizations can also promote DFM principles by cultivating a feedback loop culture and a culture of continuous development. Regular design reviews should include soliciting feedback from manufacturing teams and learning from previous design stages. DFM focuses on reducing the required number of manufacturing operations while still meeting the product’s functional requirements.

Tiara Salon

From Designing for Manufacture to Designing with Manufacturers, by Jamie Wolfond - Core77.com

From Designing for Manufacture to Designing with Manufacturers, by Jamie Wolfond.

Posted: Wed, 12 Jun 2013 07:00:00 GMT [source]

The job of your website builder is to make it as easy as possible for you to create a stunning website. Consumers and developers alike will benefit from an ecosystem where multiple hardware makers build on a common platform. We look forward to continuing on this journey to bring mixed reality to more people. All of these devices will benefit from Meta’s long-term partnership with Qualcomm Technologies, Inc., which builds the Snapdragon® processors that are tightly integrated with our software and hardware stacks. We believe a more open ecosystem is the best way to bring the power of mixed reality to as many people as possible.

Streamlined product development process

DFA stands for Design For Assembly and refers to the optimization of the product itself and the assembly process to reduce cost, effort and time. In addition, due to some size constraints of additive manufacturing machines, sometimes the related bigger designs are split into smaller sections with self-assembly features or fasteners locators. As discussed, the most important job of your salon’s website is to drive more appointments. Thus, it’s even more important that you have a salon software that manages online booking well and that is integrated with your website.

It also works to lift the hair's natural reflective properties to the surface, leaving behind a glossy finish. “Apple cider vinegar rinses work to clean debris and buildup,” says Stevens. “It’s a good pre-treatment and can work well for kids.” This rinse also works to soothe the scalp and detox the hair, while repairing damaged follicles. The brand recommends using it twice a week to also help reduce breakage and split ends. Fortunately, there are tons of hair styling products available for pretty much every hair concern. Another way to engage site visitors and showcase your salon's personality is by incorporating video and other interactive elements into your website.

A Comprehensive Guide to Design for Manufacturing (DFM) Best Practices

While planar MOSFETs have served the industry well for decades, at 20nm, they began to falter because of several factors including short-channel effects. It can be helpful to distinguish design for manufacturability from the closely related idea of a design for assembly. The COVID-19 pandemic has significantly disrupted global supply chains, highlighting the vulnerabilities in traditional design and manufacturing paradigms. In response, cloud technology is emerging as a pivotal solution, offering a way to bridge gaps and enhance resilience by transforming how data is managed and utilized across the supply chain. Working in state-of-the-art facilities at Here East, Queen Elizabeth Olympic Park, students develop their own practice with multi-disciplinary academics, designers and practitioners.

On top of that, Lavish Salon understands the benefits of blogging for a website. Hence, it never fails to impress potential customers with informative blog articles. Earlier this month, Sheffield became the sole UK company to gain the qualifications needed to make SMR reactor vessel components.

Suppliers, such as Tencom and others, not only provide the necessary materials or components but can also contribute valuable insights and guidance when it comes to design considerations for those parts. Leaders who prioritize DFM and allocate the necessary resources to the process are more likely to see positive results. Additionally, leaders who encourage communication and collaboration between design and manufacturing teams can help to break down silos and promote a culture of teamwork. A well-designed product can be manufactured quickly and efficiently, while a poorly designed product may require additional steps or processes, leading to longer production times. Broadening the scope of DFM becomes more accessible as manufacturing efficiency increases, allowing manufacturers to focus on other aspects of improving manufacturability.

DFMA Cuts Billions in Manufacturing Costs - Design News

DFMA Cuts Billions in Manufacturing Costs.

Posted: Fri, 10 Nov 2023 18:25:41 GMT [source]

The tighter the tolerance required, the more expensive the component will be to machine. When designing, specify the loosest tolerance that will serve the function of the component. There are creative ways to engineer components with lower tolerances that still perform as well as ones with higher tolerances. In the case of aluminum as an example, bar stock and plate are the two most common forms from which machined parts are made.

As manufacturing companies evolve and automate more and more stages of the processes, these processes tend to become cheaper. DFM is usually used to reduce these costs.[1] For example, if a process may be done automatically by machines (i.e. SMT component placement and soldering), such process is likely to be cheaper than doing so by hand. Depending on various types of manufacturing processes there are set guidelines for DFM practices. These DFM guidelines help to precisely define various tolerances, rules and common manufacturing checks related to DFM. In this article, I’ll lead you through the best website builders for hair salons, beauty salons, spas, barbershops, and other service-oriented businesses.

No comments:

Post a Comment